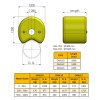

PIPE LAYING FLOATS – OVAL SERIES

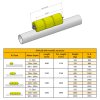

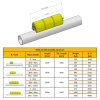

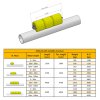

For models and characteristics please leaf through the side gallery.

To see complete datasheet, please click on specific image to enlarge

These series of floats are used to break down the immersion velocity during pipe laying operations, as well as avoiding excessive bending of the pipes at time of deployment at sea.

The floats are manufactured from an outer shell made in UV-stabilized linear virgin polyethylene. The Polyethylene used in the manufacturing process is completely recyclable (Eco-Friendly), it's fully compatible with the marine environment, and has a high resistance to UV rays.

Being linear has the advantage that it can be melted and hence repaired by hot fusion welding. The colour pigment is moulded-in and consequently not added as a coating, ensuring greater life of the colour and a big help to the environment as it never requires additional paintings, avoiding toxic dispersions in the water. Floatex polyethylene requires a minimal maintenance.

R&D laboratory daily performs tests on production samples such as tensile test, hardness test, abrasion test, UV test and Cold temperature test, colour test and other ordinary tests in the aim to ensure the quality and the reliability of Floatex polyethylene.

The floats are filled with closed-cell polyurethane foam with different density in base of the hydrostatic pressure the floats need to withstand. The polyurethane foam ensures great resistance to the leakage of air or water, ensuring unsinkability to the buoy also in case of accidental breaks of the outer shell. The polyurethane foam is 100% made and tested before production by our R&D laboratory.

Floats are fastened to the pipe by means of straps (steel or nylon).

OVAL floats, thanks to their modular construction, can house a connection steel pipe, covering different ranges of buoyancy in base of client’s requirements. Once the floats finishs their works, can be eventually released by divers or by automatic self-releasing systems allowing the recovery of the floats at surface level.

Particular attention has been given during the design process, to develop elements with adequate dimensions that can fit in standard shipping containers in the aim to contain transport costs all over the world.